The Impact

of Typhoon on PV Systems (1/2)

Most PV

modules are certified with mechanical load test, which means they are supposed

to stand the high pressure brought by storms. But why are there still damages

due to storms?

The PV modules

are fixed on the constructions, and the constructions are fixed on the roof or

foundation. Each part of the structure is equally important, because any part

fails will result in the failure of the whole system. Even though you choose

the strongest construction and best PV modules, if the screws are too weak, the

modules still fly away. Here I list some examples of storm damage on each part

of the construction.

1. Roof/ Ground structure

It

is important to check the max load resistance of the roof in the design phase,

however it is not an easy job and some EPCs only check the max roof loading

regarding the weight of the PV system. Unfortunately weight is not really

critical, but wind and snow loads are the real key factors.

According

to IEC61215, the standard used for PV module certificate, the modules are

required to stand 2400 Pa (about 245 kg/m2) corresponds to a wind

pressure of 130 km/hr (approximately ±800 Pa) with a safety factor of

3 for gusty

winds. The wind speed of typhoon is up to 202km/hr, the wind pressure will be

2344 Pa, and the module has to stand 7032 Pa (about 718 kg/m2) with a

safety factor of 3 as well.

The

weight of the PV system is roughly 20-30 kg/m2, which is very small

compare to the wind pressure 245 kg/m2 or 718 kg/m2

mentioned above. Therefore when we consider the roof loading, wind pressure is much

more important than weight.

When

wind load is considered, not only should the positive pressure on the front

side be considered, but also the negative pull off pressure. Especially when

the modules are not installed directly on the roof, the wind blow from the back

side of the module will induce huge lateral force and flipping moment on the

roof (as shown in the figure below).

|

Schematic

drawing of force and moment on additional higher construction on the roof (grey

parts are PV modules)

|

In order to prevent this kind of

external forces, additional deflectors should be used on the backside of the

construction (see the photo below). They will greatly reduce the wind pressure

and subsequently reduce the force acting on the roof. Note that the lateral

sides also need deflectors to achieve the best effect.

|

Deflectors

on the rear side of the modules

|

|

Deflectors

on the lateral side

|

2. Fixing

measures

The PV constructions are usually fixed

on the roof or foundation with screw, ballast or cement foundation, and none of

them are 100% safe (see damaged photos below), special care should be taken in

the quality of design, material and installation.

Depends on local regulations, most

structure designs have to be verified and signed by structure professional. If

the design is verified, most of the problems would be the installation quality.

For example the screw fixing strength does not match the design requirement

because it is not fixed on a beam but on thin metal sheet. This kind of problem

is not easy to be found after installation, it should be prevented with

carefully supervision during construction.

|

Weak

fixing on the roof

|

|

Insufficient

ballast weight

|

|

Insufficient

foundation strength

|

3. Construction

structure

With the FIT and subsidy decreases,

cost reduction pressure is getting higher and higher. The strength of

construction structure is also greatly influenced by the cost reduction. One

example is that the thickness of the aluminum profile is thinner and thinner for

cost reduction. The photo below shows the damage because of insufficient aluminum

thickness. The screw was pulled out directly because the aluminum profile can

not stand the pulling force.

|

Screw

pulled out because of weak aluminum profile

|

The module clamp is also a

frequently failed weak point, the photo below shows the strength is not enough

to hold the modules, and the modules are blown away.

|

Insufficient

clamp strength

|

As a summary, the design of the structure and fixing measure must be verified by structural professionals first, especially the pressure induced by the wind should be carefully calculated. The strength and thickness of the aluminum profile should be checked, they must meet the design requirement, especially the screw pull off resistance force. You can ask the supplier to provide the test report, or sampling test is even better to avoid unstable quality in the production.

Secondly, the installation quality is important, the construction fixing strength must meet the design requirement. Supervision is necessary during the construction, otherwise some improper installations are difficult to be found after installation.

At last, one frequently asked question, what to do with the blown away modules? A lot of the blown away modules still look ok, no glass breakage and not frame deformation, can these modules be re-installed?

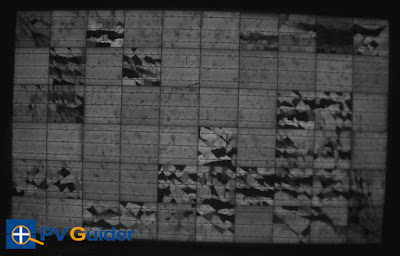

I would recommend portable EL inspection to evaluate the module damage. The two photos below are the EL images of two blown away modules. The upper one has serious cracks that must be dumped immediately. The lower one is only slightly damaged and can be re-installed.

From our experience, most blown away modules have serious micro-cracks and need to be dumped. But it also depends on the drop location and angle, we have experiences that the modules fell on wet muddy earth and there were 30% of the modules are still working well without cracks.

|

Module

with perfect appearance but serious cell cracks

|

|

Module

with perfect appearance and only few cell cracks

|

In order to explain the factors resulting

in damages, the root cause of the damage in the photos shown in this article is

simplified to be one single factor. The real root cause could be an interaction

of several factors, which needs more investigation at site to make a

conclusion.

Continue with part 2: The Impact of Typhoonon PV Systems (2/2)-Module strength

=============

About the author:

Dr. Jay Lin, Chief Consultant of PV Guider Consultancy

Task Force Leader in SEMI International Standards

Technical Committee of CNS National Standards

12 years experience (since 2004) in PV technology research and module production.

As an independent consultant, he has audited more than 50 module factories for insurance companies, investors and EPCs.

No comments:

Post a Comment